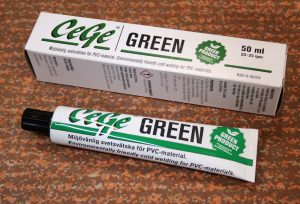

Chemical welding avoids the torch but usually not the volatile solvents. That’s where Dick Gustafsson made his mark when he took over OHLA Plast, working with his team to develop CeGe Green: cold welding for the flooring industry using a safer, environmentally friendly and non-flammable solvent.

Chemical welding avoids the torch but usually not the volatile solvents. That’s where Dick Gustafsson made his mark when he took over OHLA Plast, working with his team to develop CeGe Green: cold welding for the flooring industry using a safer, environmentally friendly and non-flammable solvent.

One catch: CeGe Green, applied from a tube, takes longer to harden compared to traditional solvents: around 12 hours compared to just 3-5 hours. But you avoid the needle nozzle that can clog up when applying traditional solvents.

“There was some initial scepticism that a slower hardening solvent could work, given how things had always been done in the industry,” says Dick Gustaffson, CEO of OHLA Plast. “Our solution was not only to suggest a new type of solvent, but also a new way of applying it.”

“Any surplus emerging from the joint can be easily removed with a tissue, thanks to its slower hardening process,” Dick explains. See for yourself with this video.

The next step at OHLA Plast: developing fossil-free PVC by teaming up with INOVYN, which recently launched a line of fossil free products under the BIOVYN brand name.

“To develop environmentally sustainable products while retaining the same quality and price as existing products is a challenge, requiring extensive research and testing”, says Dick. “But CeGe Green is a good example that this is possible even for smaller companies.”